“I have worked closely with Baren-Boym Company over the years on many projects. They have consistently provided quality design services for device concept generation, design details and computational fluid flow analysis. Baren-Boym Company has been extremely responsive to design requests even with aggressive time schedules. They are a very creative group with good insight to device performance and end-user needs. The group is a pleasure to work with.”

Barry Gellman, VP Engineering

Levitronix LLC – Medical Division

Waltham, MA

“The Baren-Boym Company provides a service that results in innovative design and direction to effective development. Concepts are well thought out and provided in a timely manner. Thorough follow-up makes Baren-Boym Company the number one choice.”

Mark Feinberg, Project Manager

Ethicon Inc, J&J

Somerville, NJ

Michael Barenboym is an elite medical device mechanical engineer, designer and the inventor of numerous life saving technologies and devices developed for fortune 500 medical device companies. He is a trusted engineering partner to some of the best in Life Sciences.

Expertise & Projects

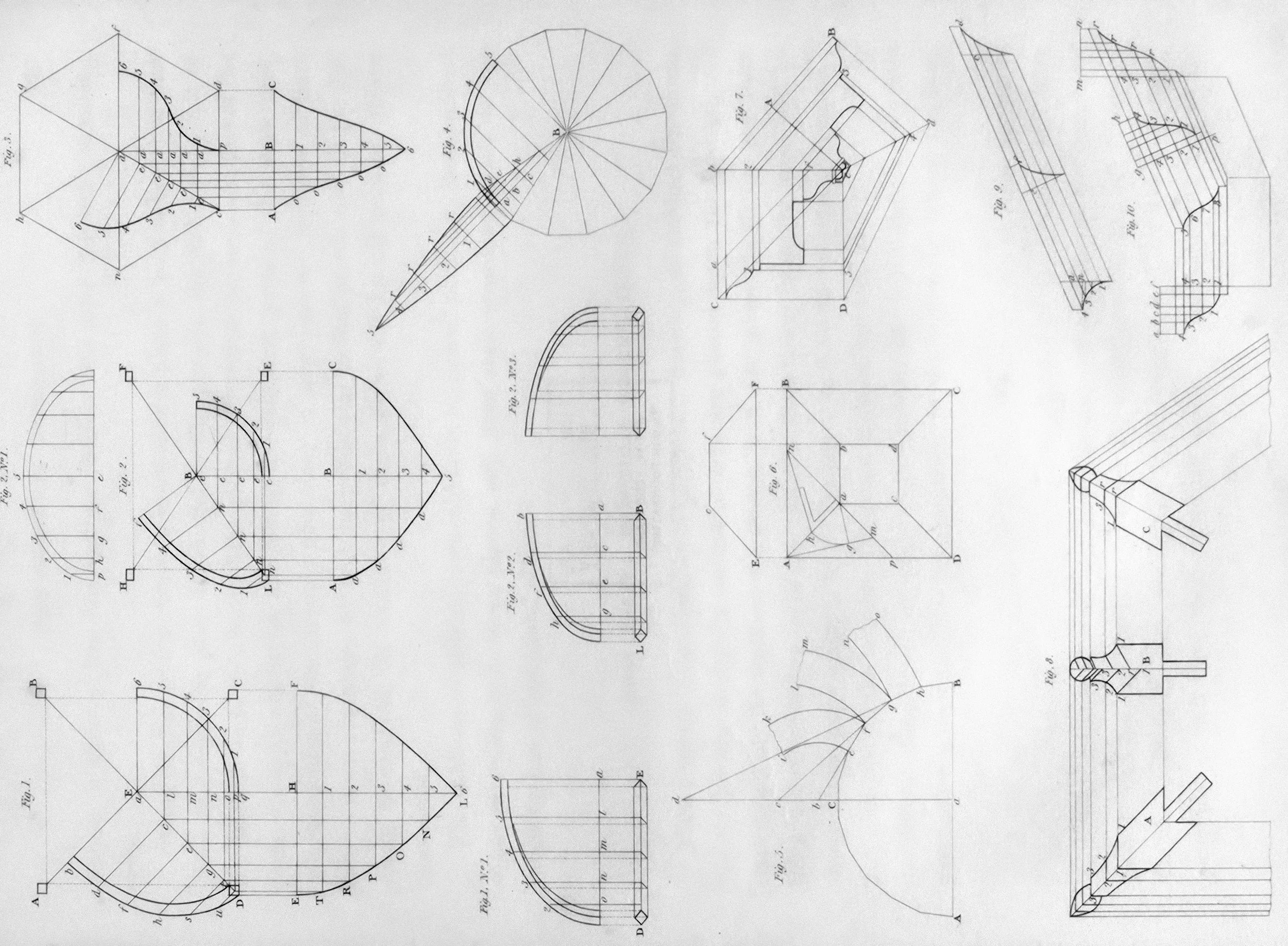

For over 35 years Michael and his team of top-notch engineering and physics professionals has been in high demand by some of the best fortune 500 companies in medical device space. All project ranged from conceptual engineering development all the way to complete engineering for manufacturability with production drawings and documentation.

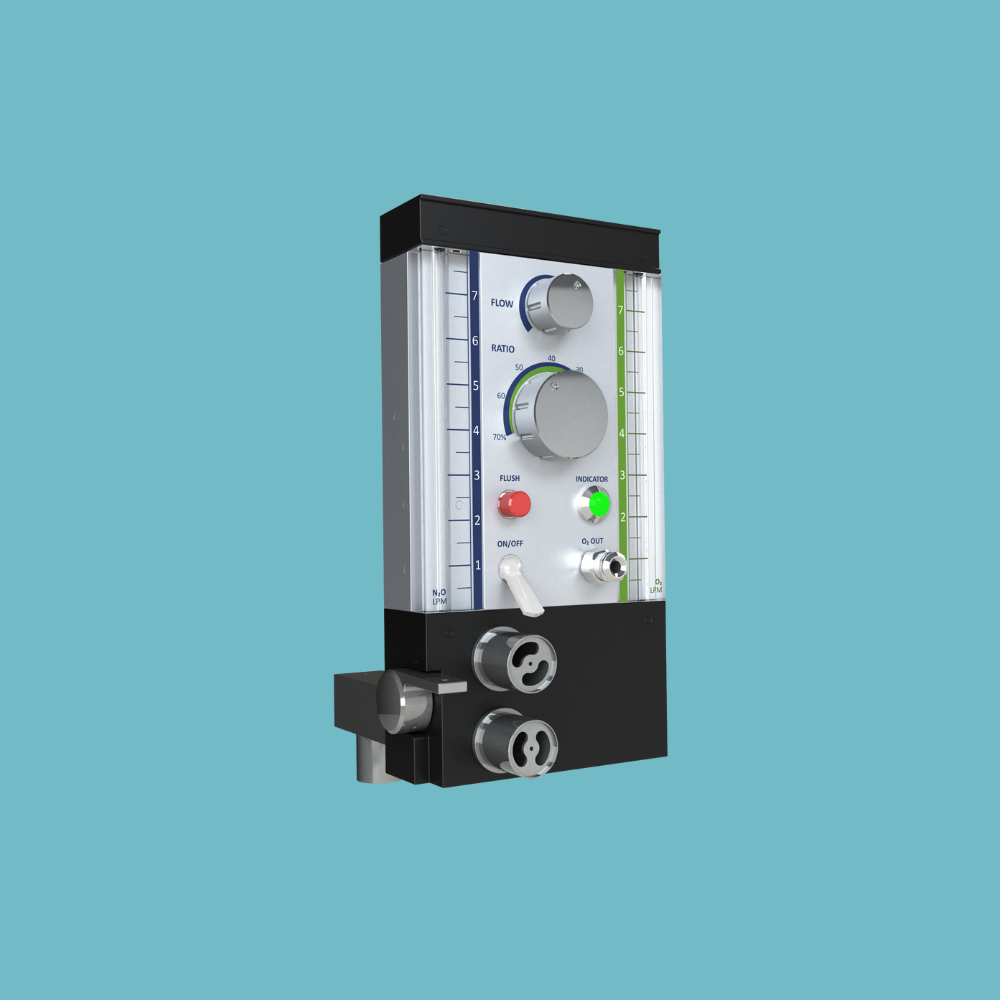

Conceptual Design – It is one of the most important phases in development cycles where you define the design concepts that answers all that doctors demand from the products. We develop conceptual designs to address the functionality, ease of use and usability of the product maintaining the visibility of manufacturing.

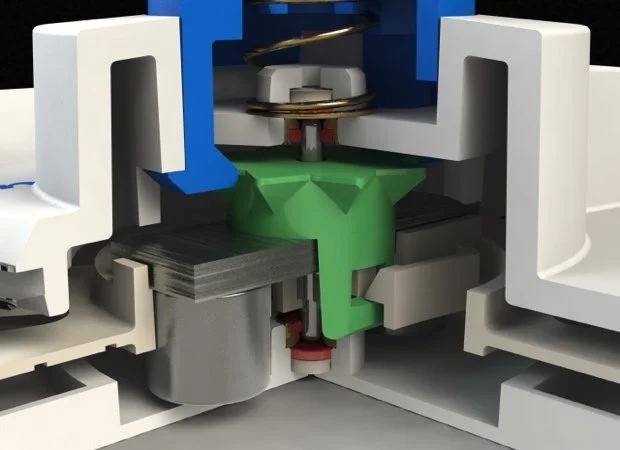

Detailed Engineering is where we take the conceptual design to next level where we design all mechanisms and structures for ease of assembly and service. Often this this the phase where we utilize our deep knowledge and ingenuity to design for reliability and costminimizing number or moving and static components, combining functionality of multiple parts into one multifunctional component. We often use material properties to achieve mechanical advantages and functionality in a simpler form.

FEA and CFD is also a very important aspect of engineering expertise we provide during the design cycle. From simple stress and deformations to strains, cyclic loading and complex computational fluid dynamics we use our experience and deep knowledge in finite element analysis to solve many problems during design cycle.

Manufacturing Liaison– our tremendous experience and knowledge of manufacturing processes is a valuable asset to our customers as we often drastically lower the manufacturing cost while simplifying assemblies and increase reliability. We are experts in injection molding, CNC machining, stamping, sheet metal, casting, thermoforming, vacuum forming and many more manufacturing techniques.

Portfolio

Cardiovascular (LVADs, valves)

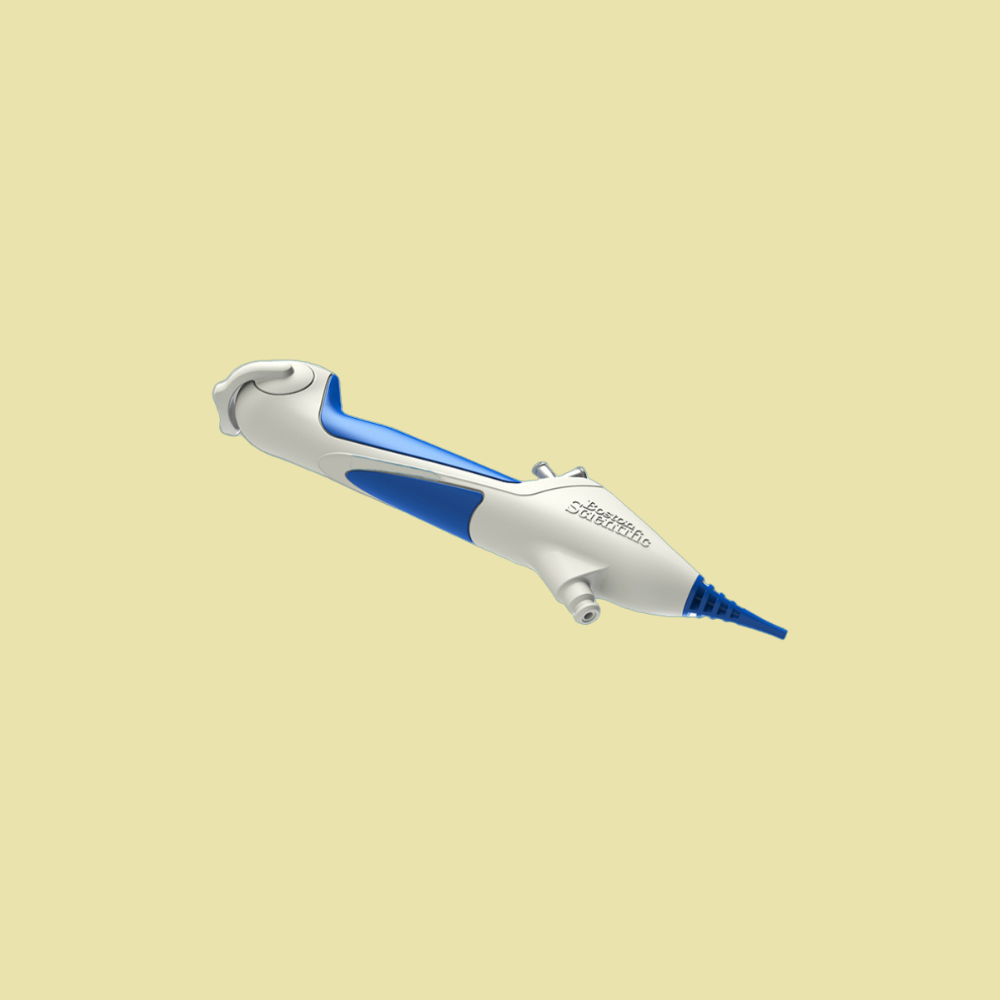

Oncology (ablation systems)

Endoscopy & Laparoscopy

Orthopedics & Spine

Catheters & Micro-invasive tools

Custom R&D & prototyping

Cardiovascular (LVADs, valves) Oncology (ablation systems) Endoscopy & Laparoscopy Orthopedics & Spine Catheters & Micro-invasive tools Custom R&D & prototyping

Trusted By The Best

Team

Michael and his team developed numerous cardiovascular devices, cancer ablation systems, endoscopy instrumentation, steerable catheters, orthopedic devices, microvasive surgical instruments, medical staplers, obstetrics and gynecological devices, ophthalmology instruments and many more

From pioneering artificial heart systems (LVADs) and steerable endoscopy/laparoscopy instruments to cancer-ablation platforms, spine-reconstructive tools, micro-invasive catheters, endoscopic staplers and suturing devices, Michael thrives on the most challenging—and ultimately most rewarding—medical-device projects. What each seemingly complex mechanism has in common is an underlying elegance: by exploiting material properties, Michael and his team coax multifunctionality from single components. Every part and assembly is meticulously engineered for manufacturability—driving down production costs while boosting durability and reliability.

With over 100 patents in the medical-device field and hundreds of successful projects to his name, Michael remains as humble and driven as ever. He’s always eager for the next opportunity to push the boundaries of what’s possible in medical engineering.

Michael’s story is quintessentially the American dream: arriving from the collapsing Soviet Union in 1990 with nothing but a curbside mattress, he persevered to earn two master’s degrees in mechanical engineering. But technical credentials alone don’t make a world-class designer. What sets Michael apart is a vision that transcends conventional thinking—an ability to anticipate both functional requirements and the human element in every device.

For the past 30 years, Michael has led engineering teams at Fortune 500 companies—including Johnson & Johnson, Smith & Nephew, Boston Scientific, Thoratec, Pentax Medical, Syneron-Candela, DePuy Spine, Codman, Terumo Heart, MedLine, ConMed, and AngioDynamics—bringing life-saving innovations from concept to clinic. His signature, user-centric process begins long before CAD drawings: he studies how medical staff receive, unbox, and prepare each device, then designs to minimize user error and maximize procedural simplicity. That dedication to usability isn’t just best practice—it’s a commitment to patient safety and clinical excellence.